You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I made this

- Thread starter Smiling Canadian

- Start date

More options

Who Replied?CERVICAL-KREMS

Veteran XV

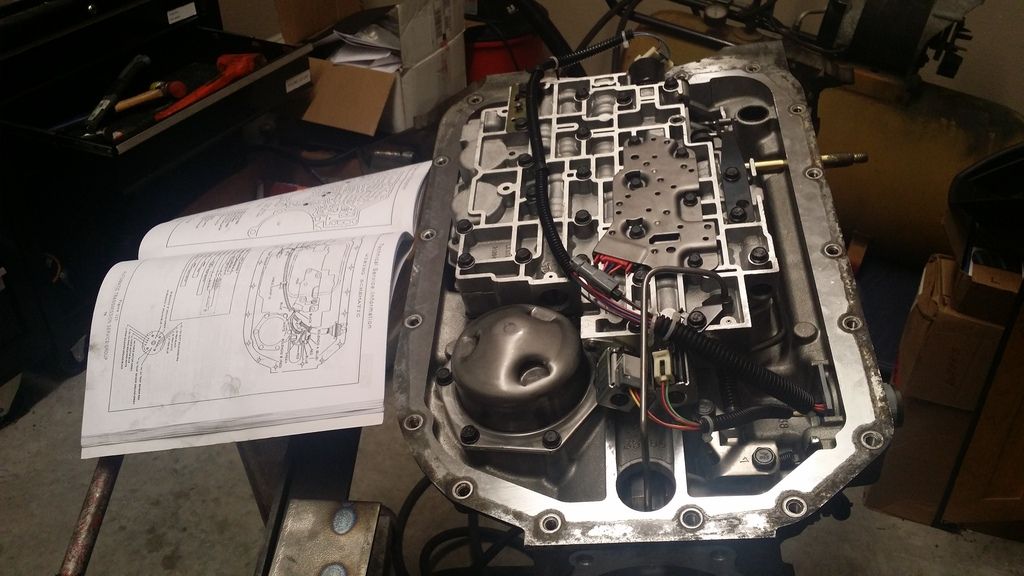

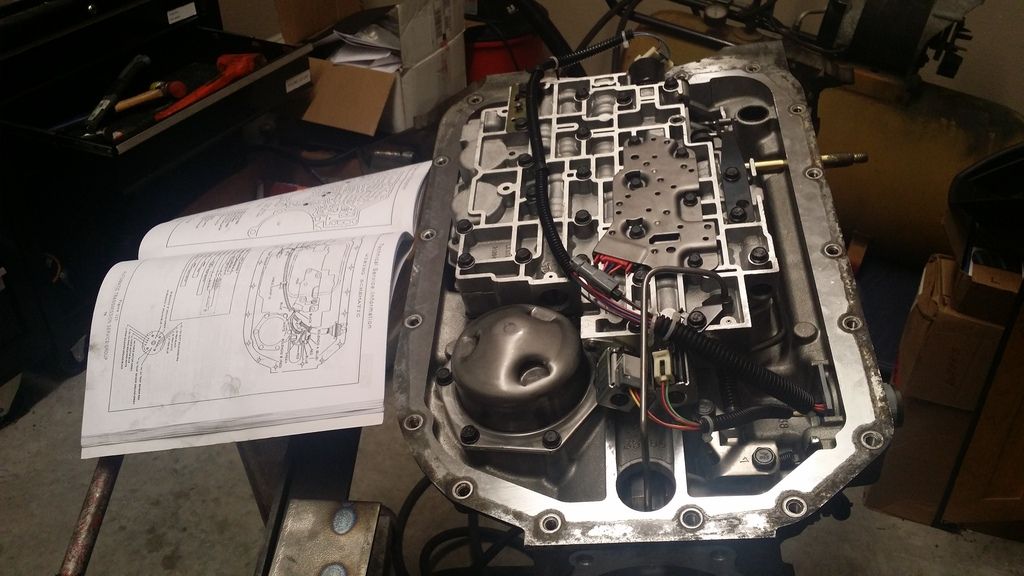

It was a 4l80e I built for my truck. I have to do another one though, so I can have a transbrake. I was too cheap the first time, which was dumb. I've never done this before, but I watched a video on youtube and did it...what a time to be alive.

Smiling Canadian

Veteran X

Don't overlook pawn shops either. Once a month I take a Saturday and check out 8 or 10 different shops. The reputable shops here all offer 30 day money back guarantees.

I recently needed a new router and found a basically brand new Porter Cable 3 1/4 hp with 1/4 and 1/2 collets and a few bits for $60. I had just looked at the same router at my industrial supplier for $529.

I even bought my KTM 300xcw from a pawn shop. 2015 with 49 hours on the meter. $3400. Dealer wanted almost $10,000.

I recently needed a new router and found a basically brand new Porter Cable 3 1/4 hp with 1/4 and 1/2 collets and a few bits for $60. I had just looked at the same router at my industrial supplier for $529.

I even bought my KTM 300xcw from a pawn shop. 2015 with 49 hours on the meter. $3400. Dealer wanted almost $10,000.

CERVICAL-KREMS

Veteran XV

What are those blocks that the hub is resting on? Are they for using presses with oddly shaped objects?

Don't overlook pawn shops either. Once a month I take a Saturday and check out 8 or 10 different shops. The reputable shops here all offer 30 day money back guarantees.

I recently needed a new router and found a basically brand new Porter Cable 3 1/4 hp with 1/4 and 1/2 collets and a few bits for $60. I had just looked at the same router at my industrial supplier for $529.

I even bought my KTM 300xcw from a pawn shop. 2015 with 49 hours on the meter. $3400. Dealer wanted almost $10,000.

This, especially for general tools like circular saws, etc. Or austrian motorcycles....

It was a 4l80e I built for my truck. I have to do another one though, so I can have a transbrake. I was too cheap the first time, which was dumb. I've never done this before, but I watched a video on youtube and did it...what a time to be alive.

http://i62.photobucket.com/albums/h81/rhoadizzle/20151013_215443.jpg/IMG]

[IMG]http://i62.photobucket.com/albums/h81/rhoadizzle/20151116_225653.jpg/IMG][/QUOTE]

Ballsy. GJ. I remember as a kid working on my 1960 bug with manuals and a fuck it, do it attitude.

Now with YouTube it isn't as risky. What a world

I'm not poor at all, almost a self made man. In 12-15 years we could afford to pay cash for a 7000 sq.ft. home but what the fuk would we do with 7 bedrooms and 6 baths? Shit like this is for people who need ostentatious displays of wealth to make up for small dicks - or in your case - a small heart.I know you can't have nice things because of your poor financial decisions. If you had any type of actual skill you would be able to pull yourself out of poverty but alas it seems I'll be supporting you with my tax dollars until I die. Don't be envious of those more successful than yourself.

Bet you can't wait for that guaranteed minimum income so you can stop posting from the free wifi at Wendys.

You inherited a business, and now you're such a precious success you're posting on the internet about a grade 10 woodworking project, and when someone calls you out for being small time you neg rep them.

I would expect better from a man with a 7000 sq.ft. home. But for someone born into wealth, I suppose you're par for the course.

Last edited:

I wish I had the time to do stuff like thisarsin you suck

Yes I'm envious.

Great thread!

I'm not poor at all, almost a self made man. In a few years we could afford to pay cash for a 7000 sq.ft. home but what the fuk would we do with 7 bedrooms and 6 baths? Shit like this is for people who need ostentatious displays of wealth to make up for small dicks - or in your case - a small heart.

You inherited a business, and now you're such a precious success you're posting on the internet about a grade 10 woodworking project, and when someone calls you out for being small time you neg rep them.

I would expect better from a man with a 7000 sq.ft. home. But for someone born into wealth, I suppose you're par for the course.

I heard smilingcanadian welds worthless hipsters to fixed gear bicycles for fun

Awesome!! I just picked one of those up last month, but it needs a lot of restoration. Yours looks great though. I was going to bring it in the house and use it to start gunsmithing. Does it have a serial plate on the right side (while facing it) of the machine? Definitely looks to be a 30s-40s model that's pretty original...that work area is almost perfect, too.

Yeah it has the serial plate. It was left out for disposal behind a lab nearby where I work. I suspect they discarded it due to the motor failing, not due to its age/condition. The motor is free but doesn't start with power. It needs additional testing. It is a 1953 (Ohio plant)

It was a 4l80e I built for my truck. I have to do another one though, so I can have a transbrake. I was too cheap the first time, which was dumb. I've never done this before, but I watched a video on youtube and did it...what a time to be alive.

I spend just as much time looking up how to do things on my phone as I do working on the car. I know I have something down when I can work on something without consulting any reference. Costs don't go down but at least my labor does as I get better + own better equipment.

The other thing is looking back and realizing "ugh i did a shit job on that" or "i should have done that differently, that was stupid". The only way you can do that is if you gain the knowledge to know better.

KingSobieski

Veteran XX

given her the D

the D kinda got everywhere

oops. not only a mouse nest but also a wasp nest. v excite.

knife sharpening stone works p gud 4 machined surfaces

stoned the surface too. can't really get all the rust out since it's lower than the milling marks. doesn't really fuck w anything tho.

v nice. loosely assembled - need 2 tune it up tomorrow n order some new knives.

the D kinda got everywhere

oops. not only a mouse nest but also a wasp nest. v excite.

knife sharpening stone works p gud 4 machined surfaces

stoned the surface too. can't really get all the rust out since it's lower than the milling marks. doesn't really fuck w anything tho.

v nice. loosely assembled - need 2 tune it up tomorrow n order some new knives.

Last edited:

KingSobieski

Veteran XX

can't really ruin his life anymore so no risk.

What are those blocks that the hub is resting on? Are they for using presses with oddly shaped objects?

Arbor plates, came with the press. Yes, they are for exactly that. Great with ball joints in control arms and steering knuckles. The rest of the parts from the top down are axle nut socket, ball joint press plate, ball joint press cup, bearing, spindle, ball joint cup. I've bent more than a few ball joint press c frames over the years, but the rest of the kit is nearly indestructible.

A ball joint set for reference. Mine came with the c frame, 2 plates, and 3 cups. I've used sections of exhaust pipe also... Usually end up crushing a few before it comes loose though.

Here's a tip for pressing bearings. Once you get the old bearing pressed out, knock the guts out of the shell and cut a relief slit in it with an angle grinder. Use it to press in the new bearing. The old shell will line up perfectly with the new bearing and the slit will allow you to remove it easily. I have a collection of junk bearing shells hanging out near the press.

Last edited:

I'm not poor at all, almost a self made man.

new sig

It was a 4l80e I built for my truck.

Yeah, I thought it looked Chevy. I haven't been into a 4L80 yet. The 60's I send to the local trans shop because they can do them in their sleep now. I've lucked out a few times and found 60's freshly rebuilt in the wrecking yards.

Post pics of your